import numpy as np

import pandas as pd

import matplotlib.pyplot as plt

from datetime import datetime, timedelta

# Set random seed for reproducibility

np.random.seed(2025)

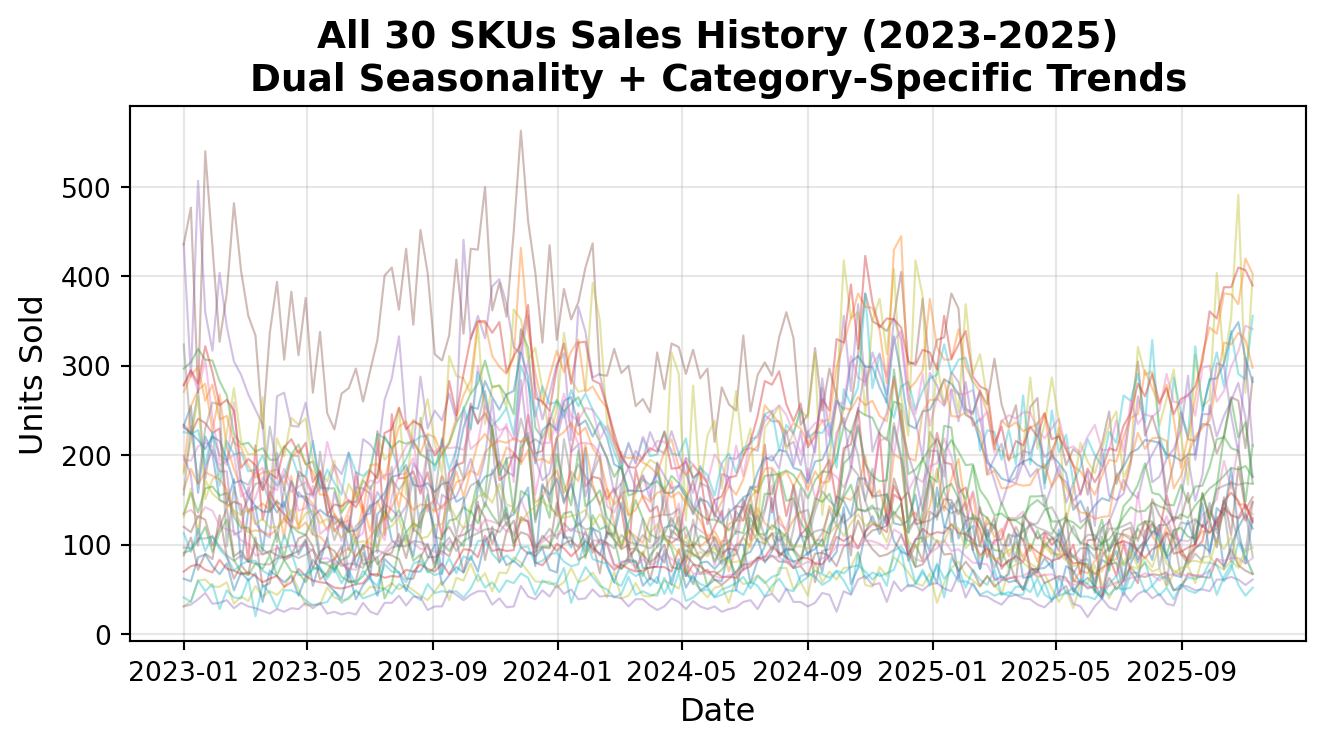

def generate_techmart_sales_history():

"""

Generate 3 years of sales history for 30 electronics SKUs.

"""

# Define 30 SKUs across 5 categories with category-specific trends

# Trend: annual growth/decline rate (e.g., 0.05 = 5% growth per year)

categories = {

'Smartphones': {'count': 8, 'trend': -0.15}, # Mature market, slight decline

'Laptops': {'count': 6, 'trend': 0.11}, # Stable with slight growth

'Headphones': {'count': 6, 'trend': 0.18}, # Growing premium audio market

'Smartwatches': {'count': 5, 'trend': 0.22}, # Emerging category, strong growth

'Tablets': {'count': 5, 'trend': -0.15} # Declining market

}

skus = []

sku_id = 1

for category, cat_info in categories.items():

count = cat_info['count']

category_trend = cat_info['trend']

for i in range(count):

# Each product has unique characteristics

if category == 'Smartphones':

base_demand = np.random.uniform(100, 410)

elif category == 'Laptops':

base_demand = np.random.uniform(90, 220)

elif category == 'Headphones':

base_demand = np.random.uniform(20, 210)

elif category == 'Smartwatches':

base_demand = np.random.uniform(20, 140)

elif category == 'Tablets':

base_demand = np.random.uniform(80, 170)

# Seasonal strength: how much seasonality affects this product (0.1-0.3)

seasonal_strength = np.random.uniform(0.1, 0.3)

# Noise level: product-specific volatility (std: 0.08-0.20)

noise_std = np.random.uniform(0.03, 0.25)

# Black Friday boost: product-specific multiplier (1.1-1.5)

bf_multiplier = np.random.uniform(1.1, 1.5)

skus.append({

'sku_id': f'SKU-{sku_id:03d}',

'category': category,

'base_demand': base_demand,

'seasonal_strength': seasonal_strength,

'noise_std': noise_std,

'bf_multiplier': bf_multiplier,

'category_trend': category_trend,

'price': np.random.uniform(30, 1200)

})

sku_id += 1

skus_df = pd.DataFrame(skus)

# Generate weekly sales from 2023-01-01 to 2025-11-15 (almost 3 years)

start_date = datetime(2023, 1, 1)

end_date = datetime(2025, 11, 15)

weeks = pd.date_range(start_date, end_date, freq='W')

sales_data = []

for _, sku in skus_df.iterrows():

for week_start in weeks:

week_num = week_start.isocalendar()[1]

year = week_start.year

month = week_start.month

# Base demand (unique per product)

demand = sku['base_demand']

# Component 1: Category-specific trend (small, linear over time)

# Calculate years elapsed from start date (2023-01-01)

years_elapsed = (week_start - start_date).days / 365.25

trend_multiplier = 1.0 + (sku['category_trend'] * years_elapsed)

demand *= trend_multiplier

# Component 2: Annual cycle (52 weeks) - peak in Nov/Dec (Q4), trough in summer (Q3)

annual_seasonality = 1.0 + sku['seasonal_strength'] * np.cos(2 * np.pi * (week_num - 47) / 52)

# Component 3: Quarterly cycle (13 weeks) - shorter-term fluctuations

quarterly_seasonality = 1.0 + (sku['seasonal_strength'] * 0.5) * np.sin(2 * np.pi * week_num / 13)

demand *= annual_seasonality * quarterly_seasonality

# Black Friday boost (product-specific multiplier)

if week_num in [47, 48]:

demand *= sku['bf_multiplier']

# Add normally distributed random noise (product-specific volatility)

noise = np.random.normal(1.0, sku['noise_std'])

demand *= max(0.5, min(1.5, noise)) # Clip to reasonable range

# Round to integer

demand = max(0, int(demand))

sales_data.append({

'sku_id': sku['sku_id'],

'week_start': week_start,

'year': year,

'week': week_num,

'month': month,

'units_sold': demand

})

sales_df = pd.DataFrame(sales_data)

return skus_df, sales_df

# Generate data

skus_df, sales_df = generate_techmart_sales_history()

print("TECHMART ELECTRONICS - SKU CATALOG")

print("=" * 120)

print(skus_df.to_string(index=False))

print("\n" + "=" * 120)

print(f"Total SKUs: {len(skus_df)}")

print("\nBy category:")

for category in skus_df['category'].unique():

count = len(skus_df[skus_df['category'] == category])

print(f" {category}: {count} SKUs")TECHMART ELECTRONICS - SKU CATALOG

========================================================================================================================

sku_id category base_demand seasonal_strength noise_std bf_multiplier category_trend price

SKU-001 Smartphones 142.001331 0.277570 0.235173 1.278227 -0.15 484.235589

SKU-002 Smartphones 179.854895 0.231474 0.138376 1.485695 -0.15 967.151836

SKU-003 Smartphones 241.113638 0.260212 0.039178 1.407783 -0.15 33.710207

SKU-004 Smartphones 190.770912 0.222183 0.230866 1.220046 -0.15 320.860405

SKU-005 Smartphones 306.581553 0.297507 0.133019 1.149315 -0.15 1101.756722

SKU-006 Smartphones 393.304495 0.155539 0.144324 1.161898 -0.15 47.114003

SKU-007 Smartphones 200.515394 0.298180 0.142891 1.450598 -0.15 108.853024

SKU-008 Smartphones 188.087659 0.193780 0.197590 1.469045 -0.15 489.837796

SKU-009 Laptops 210.781398 0.199922 0.206451 1.458632 0.11 594.091018

SKU-010 Laptops 200.230887 0.155336 0.104850 1.142030 0.11 642.082831

SKU-011 Laptops 174.306043 0.279922 0.052851 1.224698 0.11 121.380883

SKU-012 Laptops 211.923125 0.291817 0.072073 1.481608 0.11 549.536481

SKU-013 Laptops 124.245171 0.233980 0.112779 1.494186 0.11 810.475763

SKU-014 Laptops 218.890762 0.294713 0.069920 1.276549 0.11 817.168259

SKU-015 Headphones 144.177841 0.176608 0.177231 1.387934 0.18 946.536415

SKU-016 Headphones 80.986683 0.119412 0.213572 1.110089 0.18 309.358839

SKU-017 Headphones 182.850584 0.110092 0.072704 1.290362 0.18 305.164876

SKU-018 Headphones 88.229309 0.129033 0.059840 1.139115 0.18 207.471104

SKU-019 Headphones 47.458748 0.105895 0.190427 1.370478 0.18 548.940060

SKU-020 Headphones 43.726319 0.135155 0.164134 1.208759 0.18 863.933878

SKU-021 Smartwatches 63.921751 0.155961 0.223931 1.166687 0.22 147.990342

SKU-022 Smartwatches 136.894623 0.291290 0.057567 1.152603 0.22 428.359589

SKU-023 Smartwatches 80.065334 0.269516 0.155000 1.186574 0.22 757.086860

SKU-024 Smartwatches 66.345697 0.176956 0.071607 1.482957 0.22 174.054069

SKU-025 Smartwatches 30.384036 0.220347 0.161101 1.150430 0.22 749.579075

SKU-026 Tablets 109.464296 0.169059 0.104956 1.148955 -0.15 1140.611174

SKU-027 Tablets 111.850145 0.198087 0.043744 1.295709 -0.15 439.401212

SKU-028 Tablets 166.496499 0.152798 0.191875 1.299498 -0.15 1114.312833

SKU-029 Tablets 140.870051 0.114547 0.087424 1.174714 -0.15 783.925103

SKU-030 Tablets 85.573274 0.168057 0.138067 1.413962 -0.15 71.210130

========================================================================================================================

Total SKUs: 30

By category:

Smartphones: 8 SKUs

Laptops: 6 SKUs

Headphones: 6 SKUs

Smartwatches: 5 SKUs

Tablets: 5 SKUs