# DON'T MODIFY THIS DATA - These are your actual orders!

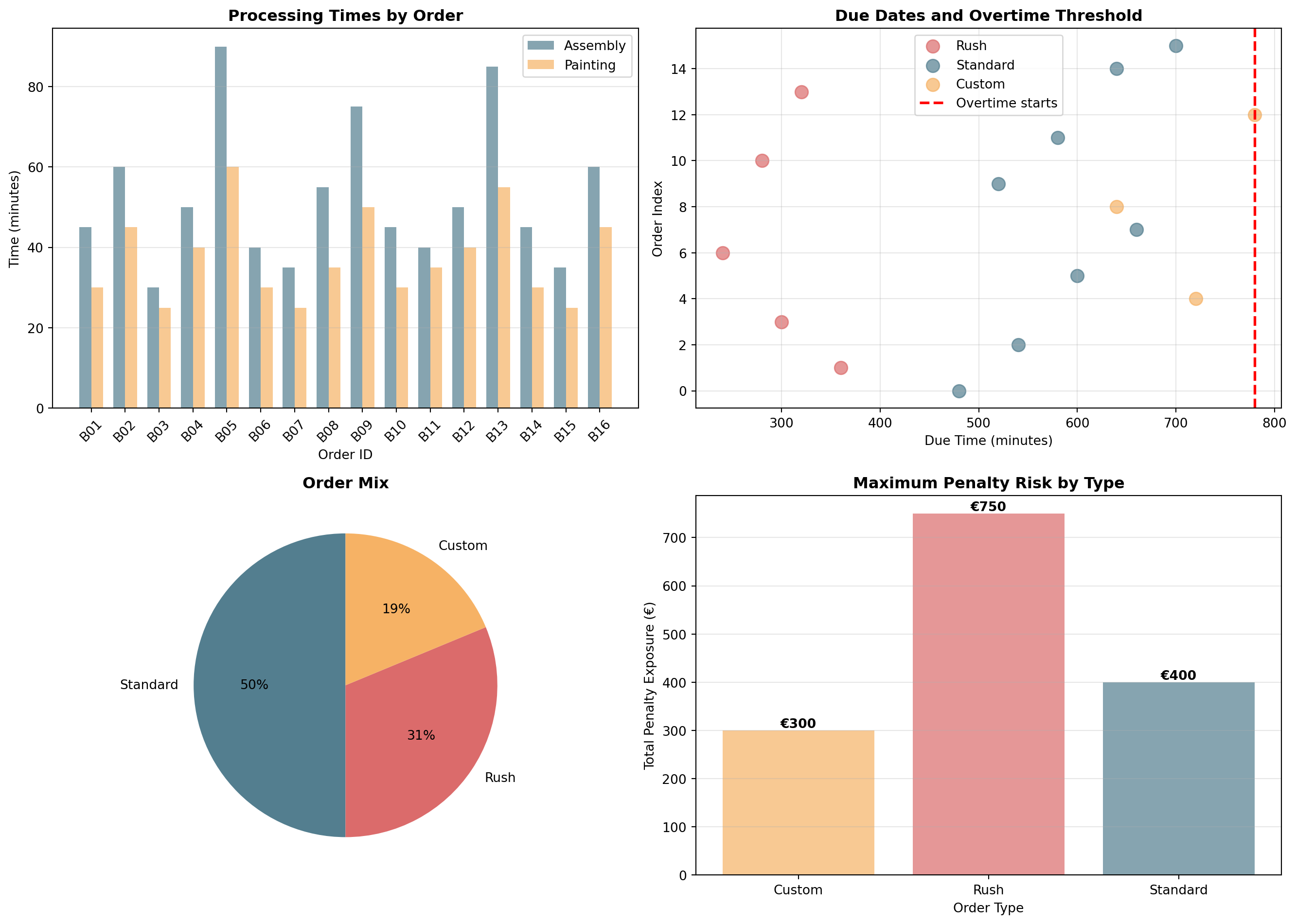

bike_orders = [

{'id': 'B01', 'type': 'Standard', 'assembly': 45, 'painting': 30, 'due': 480, 'penalty': 50},

{'id': 'B02', 'type': 'Rush', 'assembly': 60, 'painting': 45, 'due': 360, 'penalty': 150},

{'id': 'B03', 'type': 'Standard', 'assembly': 30, 'painting': 25, 'due': 540, 'penalty': 50},

{'id': 'B04', 'type': 'Rush', 'assembly': 50, 'painting': 40, 'due': 300, 'penalty': 150},

{'id': 'B05', 'type': 'Custom', 'assembly': 90, 'painting': 60, 'due': 720, 'penalty': 100},

{'id': 'B06', 'type': 'Standard', 'assembly': 40, 'painting': 30, 'due': 600, 'penalty': 50},

{'id': 'B07', 'type': 'Rush', 'assembly': 35, 'painting': 25, 'due': 240, 'penalty': 150},

{'id': 'B08', 'type': 'Standard', 'assembly': 55, 'painting': 35, 'due': 660, 'penalty': 50},

{'id': 'B09', 'type': 'Custom', 'assembly': 75, 'painting': 50, 'due': 640, 'penalty': 100},

{'id': 'B10', 'type': 'Standard', 'assembly': 45, 'painting': 30, 'due': 520, 'penalty': 50},

{'id': 'B11', 'type': 'Rush', 'assembly': 40, 'painting': 35, 'due': 280, 'penalty': 150},

{'id': 'B12', 'type': 'Standard', 'assembly': 50, 'painting': 40, 'due': 580, 'penalty': 50},

{'id': 'B13', 'type': 'Custom', 'assembly': 85, 'painting': 55, 'due': 780, 'penalty': 100},

{'id': 'B14', 'type': 'Rush', 'assembly': 45, 'painting': 30, 'due': 320, 'penalty': 150},

{'id': 'B15', 'type': 'Standard', 'assembly': 35, 'painting': 25, 'due': 640, 'penalty': 50},

{'id': 'B16', 'type': 'Standard', 'assembly': 60, 'painting': 45, 'due': 700, 'penalty': 50}

]

# Convert to DataFrame for analysis

df_bikes = pd.DataFrame(bike_orders)

print("Custom Cycles - Rush Orders")

print("=" * 50)

print(f"Total orders: {len(df_bikes)}")

print(f"\nOrder breakdown by type:")

print(df_bikes['type'].value_counts().to_string())

print(f"\nWorkload analysis:")

print(f" Total assembly time: {df_bikes['assembly'].sum()} minutes ({df_bikes['assembly'].sum()/60:.1f} hours)")

print(f" Total painting time: {df_bikes['painting'].sum()} minutes ({df_bikes['painting'].sum()/60:.1f} hours)")

print(f" Average assembly: {df_bikes['assembly'].mean():.1f} minutes")

print(f" Average painting: {df_bikes['painting'].mean():.1f} minutes")

print(f"\nTime constraints:")

print(f" Work starts: Friday 6:00 (minute 0)")

print(f" Regular hours end: Friday 19:00 (minute 780)")

print(f" Overtime rate: €100/hour after minute 780")

print(f"\nPenalty exposure:")

print(f" Total if ALL orders late: €{df_bikes['penalty'].sum():,}")

# DON'T MODIFY ABOVE!